Technical Data Sheet Piezotech FC ?

來(lái)源:本站日期:2019-05-29 13:32:44 瀏覽:301

General Properties

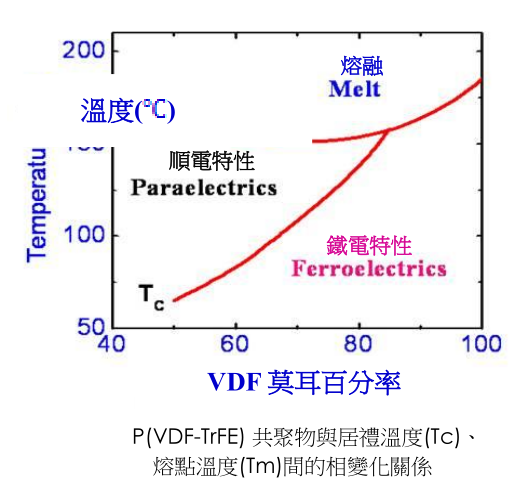

Piezotech FC TM is a range of P(VDF-TrFE) copolymers of various compositions. Piezotech FC TM Polymers are:

Piezoelectric: these polymers convert mechanical into electrical energy and inversely, these materials have high mechanical strength, high stability to chemicals, oxidants, ultraviolet and low acoustic impedance (close to water or human tissues).

Pyroelectric: these polymers convert calorific energy into electrical energy an inversely. Polymer films absorb in the 6-20µm wavelength range.

Applications printed keyboards, sensors, energy harvesting, transducers, speakers, microphones, FeFET, ferroelectric memories, IR or fingertips detectors…

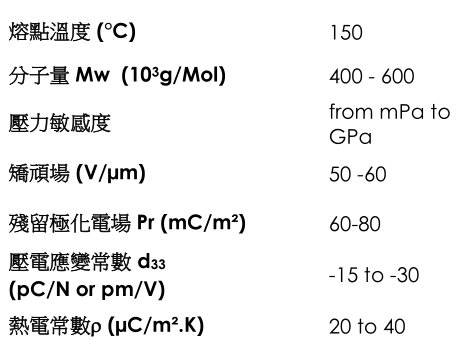

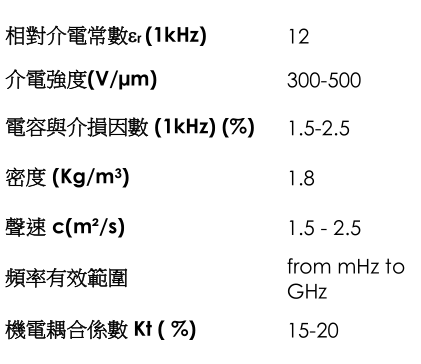

Piezotech FC TM typical values

Processing

Solubilization & Filtration

Piezotech RT TM polymers are soluble in ketone solvents (Methyl Ethyl Ketone (MEK), Methyl Isobutyl Ketone (MIBK), cyclo-hexanone, cylopentanone etc…), Dimethyl formamide (DMF), Dimethyl Sulfoxide (DMSO), Phosphate solvents (Triethyl phosphate) etc… In order to get homogeneous films with high electrical breakdown a filtering step of the solution is required, it will remove impurities and prevent gel formation.

Film Formation

Solution can be deposited via solvent cast, screen printing or spin-coating or other printing techniques on a glass, silicon, Polyimide, PEN… substrate under clean atmosphere until an homogeneous and dry film is formed.

Film annealing

Annealing is a critical step to provide film with the best properties, it will control crystallization of the material and enhance electrical as well as mechanical properties. Rapid annealing may be obtained on thin films using Infrared or Flash annealing.

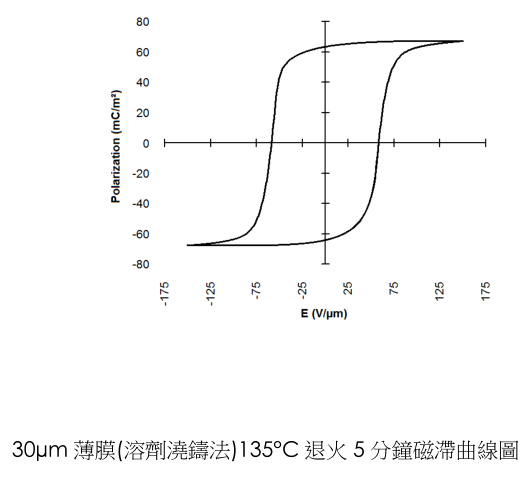

Film and deposition poling

To activate a copolymer material, a poling step is necessary. An electric field above the coercive field value (ie 50V/µm) and typically twice the coercive field value has to be applied. For thin layers of printed devices, electric field can be applied directly through the device’s electrodes. For thicker films, poling can be done trough contacting and pressing the film between electrodes and applying an increasing low frequency voltage. For large surface, one can use corona poling.

Clean-up

The product can be cleaned up with ketones solvents (MEK (methyl ethyl ketone), Cyclopentanone …)